Deutsche Bahn Digital Maintenance Vehicles x Partium

IT support helps employees in DB's maintenance facilities find spare parts and suitable materials more quickly

Request demo

Lets Chat.

The Partium solution speeds up the retrieval of materials for maintenance in DB's facilities

The maintenance of modern multiple units, locomotives and railway cars is becoming increasingly complex. Various series, varying levels of expertise and experience among employees, many components that sometimes look confusingly similar: Identifying components correctly and searching for spare parts in the warehouse often costs valuable working time, especially during unscheduled maintenance, and may even keep several mechanics busy. Partium has therefore developed an IT solution, "DB Mat.ID", together with the Deutsche Bahn (DB) "Digital Maintenance Vehicles" (DIFa/Digitale Instandhaltung Fahrzeuge) group program. This greatly simplifies and speeds up the search for the right material.

The Deutsche Bahn Digital Maintenance Vehicles (DIFa) group program

Deutsche Bahn's (DB) train fleet is steadily growing. DB is therefore creating additional capacity in maintenance, including through digitalization. This increases the availability of its vehicles and deploys its resources in an even more targeted manner. DB has set up the "Digital Maintenance Vehicles" (DIFa) group program to ensure a stringent group-wide approach. There are currently 18 projects in the DIFa portfolio.

The AI-based material recognition project

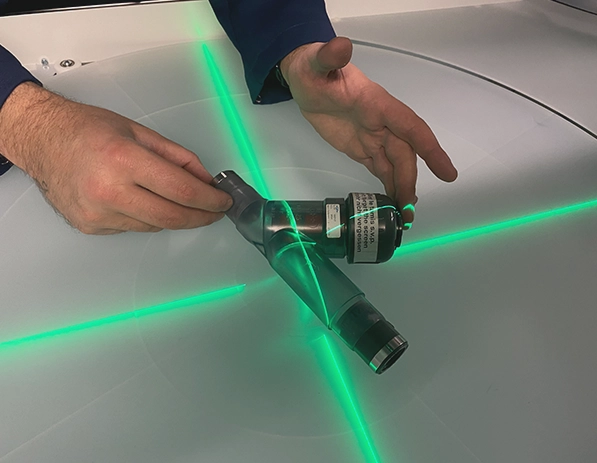

One of the measures in DB's "Digital Maintenance Vehicles" (DIFa) group program is to support employees in the group's facilities with a digital solution for identifying spare parts. Pioneering work in this area was carried out in the DB Fernverkehr (Long-Distance) business unit: The "iMate" solution, which recognizes materials using artificial intelligence and Partium helped to develop, has been deployed there since 2019. This allows mechanics to identify components with the help of a single photo.

Because "iMate" works well, is scalable and generates significant added value for the employees in the plants, the solution was selected for use in other business areas in the DB DIFa group program. Pilot projects showed considerable added value at DB Cargo, DB Regio (Commuter trains), DB Fahrzeuginstandhaltung (Engine maintenance) and the DB Netz (Network) machine pool. Testimonials from employees were also extremely positive. Material search times were significantly reduced by using the digital solution. As a result, all five business units decided on a nationwide rollout.

The result – The DB Mat.ID app

After successful pilot phases, the participating business units have agreed on a standardized solution under the name "DB Mat.ID". It helps employees to identify components directly – either with an AI-supported text search or via image recognition. To do this, a dismantled part is photographed directly on the vehicle using a tablet PC or smartphone, DB Mat.ID then displays all relevant material information within seconds, such as SAP number, manufacturer name and number, storage location and stock. In the final stage, 12,000 employees in 64 DB plants will be able to find more than 110,000 components via the DB Mat.ID app.

To achieve a high recognition accuracy in the image search, the components are digitized in a standardized photographic process. The images are used to teach artificial intelligence (AI). The five business areas involved work together and exchange digitized materials with each other, for example. In the maintenance facilities, the use of DB Mat.ID significantly reduces search and picking times, with the result that other business units and areas of activity at DB have already expressed interest in the solution.

Fast, efficient & mobile material identification

Fast, efficient & mobile material identification

DB Mat.ID supports mechanics reliably and directly on the vehicle when searching for materials. There is no need to go to supervisors or materials management, saving employees valuable time.

Support for all experience levels

Support for all experience levels

The DB Mat.ID solution by Partium supports mechanics with different levels of experience in finding materials – both new and longstanding employees benefit from intelligent search.

Synergy effects

Synergy effects

Through the initiative of the group's Digital Maintenance Vehicles (DIFa) program, DB as a whole benefits from group-wide infrastructure, data generation and data usage.

More about other DB projects

DB Mat.ID is an excellent cross-business unit solution that supports our mechanics in identifying materials and represents real added value for Deutsche Bahn.

Lukas Cambeis,

Group program Digital Maintenance Vehicles (DIFa)

PMO & Professional Principles DIFa (TTPXDIFa)